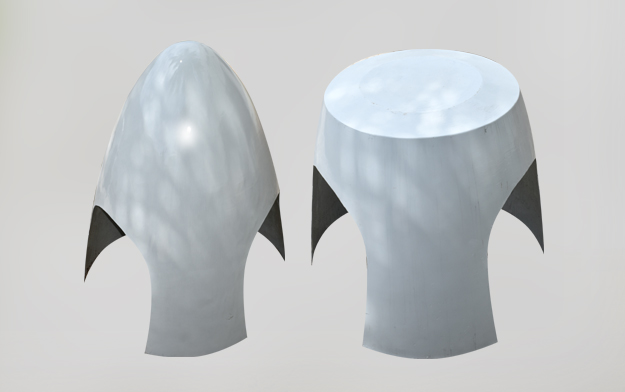

You get individually customized, market-leading, high-quality spinner covers that shield and protect key components inside the rotor hub.

Our spinner covers protect key components. The spinner cover is mounted on the rotor hub and manufactured in composites for low weight, temperature resistance, non-corrosion and rigidity. The design varies across the different types of turbines. However, the same specifications and requirements to shelter key components apply.

Dhandapani Renewables Pvt Ltd

Dhandapani Renewables Pvt Ltd